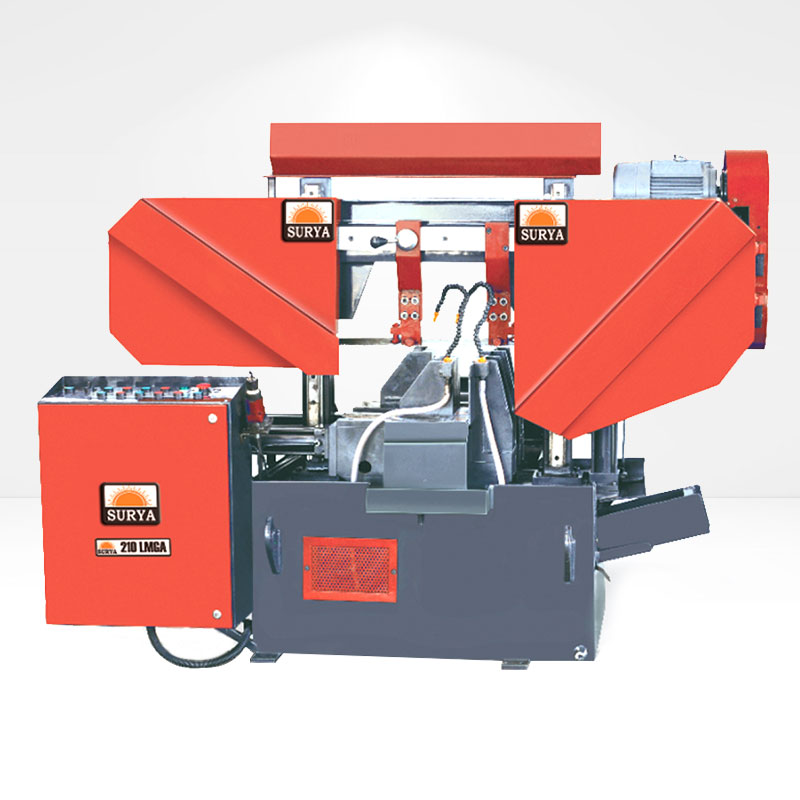

Automatic Bandsaw Cutting Machine

Year Of Establishment 1991

Automatic Bandsaw Cutting Machines - Made With Cutting-Edge Technology

Surya Machine Tools India Pvt. Ltd. is a renowned company specializing in the design and construction of Automatic Bandsaw Cutting Machines. Our Automatic Bandsaw Cutting Machines are meticulously engineered to provide accurate and reliable cutting solutions for a wide range of materials, including metal, graphite, hard plastic, aluminum, stainless steel, die steel, and more.

As one of the leading Automatic Bandsaw Cutting Machine Manufacturers in India, we have established ourselves as a trusted name with a track record of delivering high-quality machines that cater to the diverse needs of our customers. We continually invest in research and development to enhance the performance and capabilities of our machines. Our team of skilled engineers and technicians works tirelessly to incorporate the latest advancements in automation, control systems, and cutting-edge technologies into our designs.

Need Further Assistance With Our Products or Have Any Queries?

Technical Details Of DCA/DCSA

| Specification | 210 DCA / DCSA | 260 DCA / DCSA | 300 DCA / DCSA | 360 DCA / DCSA | 460 DCA / DCSA | 525 DCA / DCSA | 650 DCSA | 800 DCSA | 1000 DCSA | 1250 DCSA | 1500 DCSA | 2000 DCSA |

| Cutting Capacity in mm | ||||||||||||

| Square | 210 X 210 | 260X260 | 300X300 | 360X360 | 460X460 | 525X525 | 650X650 | 800X800 | 1000X1000 | 1250X1250 | 1500X1500 | 2000X2000 |

| Round | 210 | 260 | 300 | 360 | 460 | 525 | 650 | 800 | 1000 | 1250 | 1500 | 2000 |

| Cutting Speed in mtr / min | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 |

| Blade Size (in mm) | 3505 X 27 X 0.9 | 3820X34X1.1 | 4100X34X1.1 | 4860X34X1.1 | 5800X41X1.3 | 5800X41X1.3 | 6900X54X1.3 | 8800X67X1.6 | 10300X67X1.6 | 13100X67X1.6 | 16300X67X1.6 | 19500X67X1.6 |

| Blade Tension | Manual/Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Saw Motor Capacity in H.P. | 3 H.P. | 5 H.P | 5 H.P | 5 H.P | 7.5 H.P | 10 H.P | 12.5 H.P | 15 H.P | 20 H.P | 20 H.P | 25 H.P | 30 H.P |

| Hydraulic Motor in H.P. | 1 H.P. | 1 H.P. | 1 H.P. | 1 H.P. | 1 H.P. | 2 H.P. | 2 H.P. | 2 H.P. | 2 H.P. | 3 H.P. | 3 H.P. | 3 H.P. |

| Coolant Motor in H.P. | 0.16 H.P. | 0.16 H.P. | 0.16 H.P. | 0.16 H.P. | 0.16 H.P. | 0.16 H.P. | 0.25 H.P. | 0.25 H.P. | 0.25 H.P. | 0.25 H.P. | 0.50 H.P. | 0.50 H.P. |

| Job Indexing Available in | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model | DCA Model |

| Approx Weight in Kgs DCA | 1650 | 2050 | 2150 | 2320 | 2715 | 3150 | 5320 | 6480 | 8750 | 11500 | 13240 | 17800 |

| DCSA | 1100 | 1580 | 1580 | 1810 | 1840 | 2460 | 4400 | 5260 | 7210 | 9600 | 11450 | 15500 |

| Face Accuracy | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm |

Technical Details Of LMGA / LMGS

| Specification | 210 LMGA / LMGS | 300 LMGA / LMGS | 360 LMGA / LMGS | 460 LMGA / LMGS | 550 LMGA / LMGS | ||||||

| Cutting Capacity in mm | |||||||||||

| Square | 210X210 | 300X300 | 360X360 | 460X460 | 550X550 | ||||||

| Round | 210 | 300 | 360 | 460 | 550 | ||||||

| Cutting Speed in mtr / min | 20-100 | 20-100 | 20-100 | 20-100 | 20-100 | ||||||

| Blade Size (in mm) | 4100 X 27 X 0.9 | 4860 X 34 X 1.1 | 5450 X 41 X 1.1 | 6400 X 41 X 1.3 | 7600 X 54 X 1.3 | ||||||

| Blade Tension | Manual/Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | ||||||

| Saw Motor Capacity in H.P. | 3 H.P. | 5 H.P | 5 H.P | 7.5 H.P | 10 H.P | ||||||

| Hydraulic Motor in H.P. | 1 H.P. | 1 H.P. | 1 H.P. | 1 H.P. | 2 H.P. | ||||||

| Coolant Motor in H.P. | 0.16 H.P. | 0.16 H.P. | 0.16 H.P. | 0.16 H.P. | 0.25 H.P. | ||||||

| Job Indexing Available in | LMGA Model | LMGA Model | LMGA Model | LMGA Model | LMGA Model | ||||||

| Approx Weight in Kgs LMGA |

1650 | 2150 | 2320 | 2715 | 3150 | ||||||

| LMGS | 1100 | 1580 | 1810 | 1840 | 2460 | ||||||

| Face Accuracy | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | 0.15/100mm | ||||||

Our Testimonials

Excellent machine with easy operation and maintenance, prompt service , mr satyendra singh’s very supportive nature

SMT ADVANCE TECH PRIVATE LIMITED

Really very affordable prize and trustable brand …and owner behaviour is very cool and nice..

Atul Singh

Best circular saw and Band saw machine manufacturers in India with optimal price range along with heavy duty functioning.

Dr. Surya Pratap Singh Chauhan

Key Success Factors

Get High-Quality Automatic Bandsaw Cutting Machine at a Reasonable Price

Every Surya Automatic Band Saw Cutting Machine undergoes rigorous testing and quality control procedures to ensure its performance, durability, and safety. We utilize top-grade materials and components, combined with advanced manufacturing techniques, to create robust automatic band saw machine that can withstand the demands of heavy-duty industrial applications.

We offer customization options to tailor our machines to fulfill the unique and specific requirements of our clients. With a solid reputation for excellence and a commitment to customer satisfaction, we continue to lead the way in the manufacturing of Automatic Bandsaw Cutting Machines. Choose us for quality products as we are one of the trusted Automatic Bandsaw Cutting Machine Suppliers in India.

Exceptional Features Metal Cutting Band Saw Machine to Meet the Needs of Various Industries.

Features Of Automatic Bandsaw Cutting Machine

- The machine features a double-column ground, hardened, and hard chrome-plated design for better movement of the cutting arm.

- Automatic height adjustment of saw frame to match the job height.

- Use a tungsten carbide face guide with two rows of ball bearings to ensure a better guide of the bandsaw blade.

- A heavy-duty modified gearbox is incorporated to provide increased torque.

- The machine has a rotary-type wire brush for effective blade cleaning.

- An independent electrical control panel equipped with a PLC.

- To achieve precise length settings, an imported mechanical position indicator is used.

- The piece counter display is integrated into the PLC system.

- The machine offers the convenience of multiple job indexing capabilities.

Applications Of Automatic Bandsaw Cutting Machine

- Aviation industries

- Metallurgy sector

- Chemical industry

- Heavy Fabrication

- Construction sector

- Automobile sector

- Power and forging sector

For More Information

Office Address

No. 136, Industrial Area No. 2, A.B Road, Dewas-455001, Madhya Pradesh, India

Call Us Now

(+91) 7272-406424

(+91) 7869-915333

Mail Us Now